Square Duct manufacturing Auto Coil Line Ⅲ

Square Duct manufacture auto Coil line Ⅲ for the Manufacture of Air-condition Rectangular Ducts

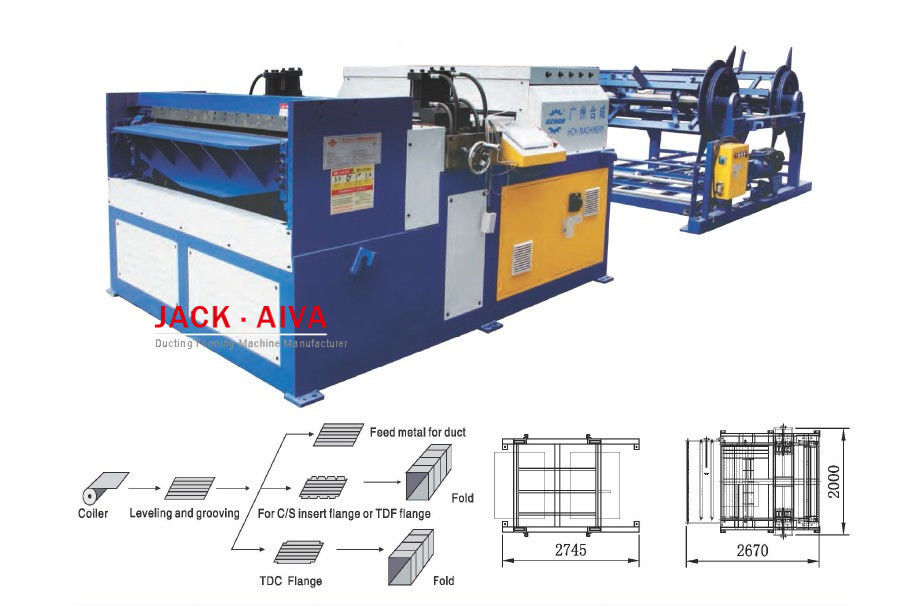

Rectangular Duct Forming Machine / duct manufacture auto coil line Ⅲ the one of the popular machines in this HVAC Fabrication Machinery industry, consists of a metal feeding frame, leveling and grooving equipment, hydraulic punching square notch equipment, hydraulic cutter and folder. The electrical control system uses a computer with a closed-loop and servo-system to increase the precision and reliability of the manufacture line.

This HVAC Fabrication Machine maximum working speed is 10m/min. The length tolerance is ±o.5mm. The diagonal line tolerance is ±0.8mm. One team will produce 1000m2 of square duct by using this system

Rectangular duct manufacture auto coil line is special for manufacture making HVAC square air ductwork from GI metal sheet coil.

Rectangular Duct Forming Machine Ⅲ or Duct manufacture auto coil line Flow Chart

Main parameters -Square Duct manufacturing Auto Coil Line Ⅲ

| Model |

Thickness

(mm)

|

Max width

(mm)

|

Max speed

(m/min)

|

Coiler Capacity

(Kg)

|

Weight

(kg)

|

Dimension

(L x W x H)mm

|

| AML- III |

0.6-1.2 |

1300 |

16 |

6000*2 |

3500 |

2450×2160×1300 |

| 1500 |

16 |

6000*2 |

4000 |

2450×2460×1300 |

| AML- III-D |

0.6-1.5 |

1300 |

16 |

6000*2 |

3800 |

2450×2160×1300 |

| 1500 |

16 |

6000*2 |

4300 |

2450×2460×1300 |

We can make the different max width and coil different max weight according to clients’ requirement

Usage Features

Duct Manufacture Auto Line Ⅲ can be used for HVAC Fabrication, either a stand alone system or the start of a complete automatic fabricating system.

Metal sheet Cut-to length function can be got combined with plasma cutter;

"C","S" insert cleat notch, which can be used with "C" cleat and “S” insert flange machine;

Different connecting methods can be combined with TDF flange machine and TDF folding machine;

It is able to punch all kinds of notch in angle steel flanges and "Z" shape flanges. Also " ","

"," " and "

" and " "shape can be formed, and working with seaming machine to complete the ducts System;

"shape can be formed, and working with seaming machine to complete the ducts System;

Able to punch TDC notch and press to form insert flange to produce " " shape duct; able to be used with connecting machine and insert flange to give a complete the ducts system.

" shape duct; able to be used with connecting machine and insert flange to give a complete the ducts system.

Basic Component - Square Duct Manufacture Coil Auto Line Ⅲ

The following are the main devices including the rectangular duct forming equipment III

Electrical un-coiler: 2 sets (4 coils plates)

Feeding, flatting and beading rolls: 1 set

Notching device: 1 set

Hydraulic cutting and folding device: 1 set

Hydraulic cutting machine 1 set

PLC control system: 1 set (With touch screen, servo control system)

Hydraulic system: 1 set

TAG: Rectangular Duct Auto COIL Line, Duct manufacture auto coil line, Rectangular Duct coil line, Square Duct Manufacturing line, Duct Auto Coil line, Rectangular Duct Auto Coil Line, Square Duct Manufacture Auto Coil line Ⅲ

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!