TDC Flange Duct Fabrication Machines - Economical Solution

TDC Flange Duct Fabrication Machines

TDC (transverse duct connection) is a separate manufactured flange (slip on flange) that you can fix it on the main duct.

slip-on duct connections enable the fast, cost-effective and tight connection of rectangular air ducts. Almost any size and sealing class is possible. Comprising of slip-on duct flanges of different sizes and a variety of different corners, our 4-bolt connection systems allow for the appropriate connecting frame to be produced for every requirement (duct size, volume flow, pressure ratios, air tightness). Flanges and corners are also available made of stainless steel (AISI 304 or AISI 316) or aluminum.

With injected sealing compound, these flanges are suitable for sealing class C or D (Premium-Flange) without additional sealing measures along the longitudinal edge of the flange

ADVANTAGES:

· All the production process is done in the factory and it arrives ready to install, in some cases the straight ducts are delivery in two parts ("L" sections) for reduce the cost of freight.

· This provides a solid and strong metal connection with a substantial savings in labor cost.

· Easy and quick installation No specialized labor or tools are required.

· Good presentation.

· Re-usable in case of moving or system expansion

· Less leaks due to sealing system

· Intermediate reinforcement is not required generally.

· Easily adaptable to any heights for duct installation

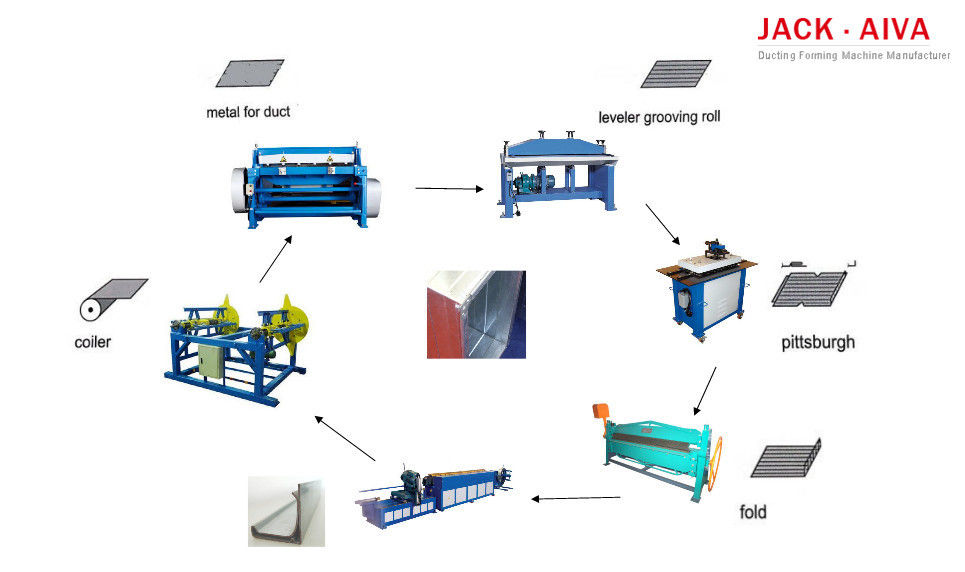

TDC flange roll former can be combined with other products of our manufacturer, de-coiler, shearing machine, beading machine, folding machine, Pittsburgh lock machine, etc. The ducts manufactured are up to standard and reliable.

Main Parameters- Economical duct manufacturing machines

- Employee: 6-12 skilled operator

- Duct production capacity: 2000m2/8hours

- Power: 12kw

- Production area: 50-60m2

Main Components- Economical duct manufacturing machines

| No. |

Item |

Type |

| 1 |

De-coiler |

5tons*1300mm |

| 2 |

Power shearer |

Q11-3*1300 |

| 3 |

Reinforce Beading Machine |

G-1.5*1250-5 |

| 4 |

Lock former |

LC-12DR |

| 5 |

Folding Machine |

WA-1.5*1300 |

| 6 |

TDC flange roll former |

T30 |

TDC Flange Duct Fabrication Process

TAG: Rectangular Ductwork Machines, HVAC Duct Making Machine, duct manufacture machine Duct making machine, Duct-manufacturing-machines

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!