Volume Control Damper Frame Machine, Air Duct VCD Damper Machine

Air Duct Volume Control Damper & Back-draft Damper Casing Production Line

A Volume Control Damper (VCD) is a valve that stops or regulates the flow of air inside a duct, VAV box, air handler units, or other air handling equipment. A VCD may be used to cut off central air conditioning to an unused room, or to regulate it for room-by-room temperature and climate control.

Its operation can be manual or automatic. Manual dampers are turned by a handle on the outside of a duct. Automatic dampers are used to regulate airflow constantly and are operated by electric Actuator, in turn controlled by a thermostat or building automation system.

Our Volume Control Damper VCD casing production line is developed based on fully absorbing abroad competitors' advanced experience, it applied new crafts, new techniques and solved effectively many problems brought plate without any damages. this Volume Damper & Back-Draft Damper frame produced by it doesn't need weld and rust prevention treatment, and guarantees the zinc coating of zinc with any damages, which conforms to the national environmental protection requirements, its full line achieved standardized, intelligent and high efficiency production, reduced product period greatly, saving time and labor, and reduced the scrap rate of product, which is the idea equipment for batch production of fire VCD damper.

Technology specification - Volume Control Damper and Back Draft Damper Casing Making Machine

The VCD Damper Casing production Line is designed according to 1.0-1.6mm thickness GI Steel normally. The whole Damper making machine is consisted of uncoiler (manual), leveler and hydraulic press, hydraulic cutter, strip feeding table, roll form machine, hydraulic punching, run out table, hydraulic system, electrical control system, etc.

The VCD damper roll forming line Technology process is as following

Coil unwinding → sheet guiding → leveling → punching holes moulds (5 sets) → punching shaft hole (16mm → temperature sensing hole (20mm) → cold forming → punching moulds (Repair profile shape) →cut to length → receiving Frame → hand folded into a frame

Main Parameters - Volume Control Damper and Back Draft Damper Making Machine

- Raw material: GI steel Thickness: 0.8-2.5mm

- Coil width: According VCD frame profile drawing

- Coil weight: ≤3000kg

- Line speed: 1-15m/min (adjustable)

- Length tolerance: ±0.3mm/1000mm

- Punching hole distance tolerance: ±0.3mm/1000mm

- Min frame sizes:120*120mm

- Profile Flange: Fixed width 150 mm (VCD Flange 35mm) (According to customer requirement)

- Processing method: cut To length / single straight piece / 口 type / L type

- Control mode: PLC control

- Dimensions: about 23000 × 1000 × 1200mm (length × width × height)

- Total power: about 31KW

- Total weight: 12000kg

-. Efficiency: 400-600pcs frame/ 8 hours

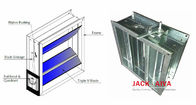

Volume Control Damper (VCD) and Back Draft Damper frame

The air volume regulating valve is an indispensable central air conditioning terminal fitting for ventilation, air conditioning and air purification engineering of industrial buildings. It is generally used in air conditioning and ventilation system piping to adjust the air volume of the branch pipe, and can also be used for fresh air and back. Mixed adjustment of the wind.

The following profile drawing of the type VCD damper frame for reference.

Customized Volume Damper and Back Draft Damper frame are welcome!

TAG: VCD Control Damper Casing, HVAC Damper, Volume Control Damper Casing Production Line, Back-draft Damper Casing Production Line, VCD Damper Frame

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!